PBI MAX™ LP

The Ultimate in Lightweight Protection

2X Better Tear Strength, As Received*

3X Better Tear Strength, After UV*

More Large Metro City Users*

*Compared to competitive PBI Outershell

The future of lightweight outer shell protection has arrived!

As the exclusive North American outershell provider of PBI LP, Safety Components is proud to introduce PBI MaxTM LPTM. Lighter, stronger, with enhanced break open protection — it’s truly lightweight perfected.

Specifications

6.0 oz PBI Max LP

Weight: 6 oz

-70% PBI LP / Para-Aramid spun yarns

-30% 400 denier DuPont Kevlar filament

Weave: Comfort Twill with Filament Twill Technology

Color: Gold and Black

PBI Fiber (Traditional)

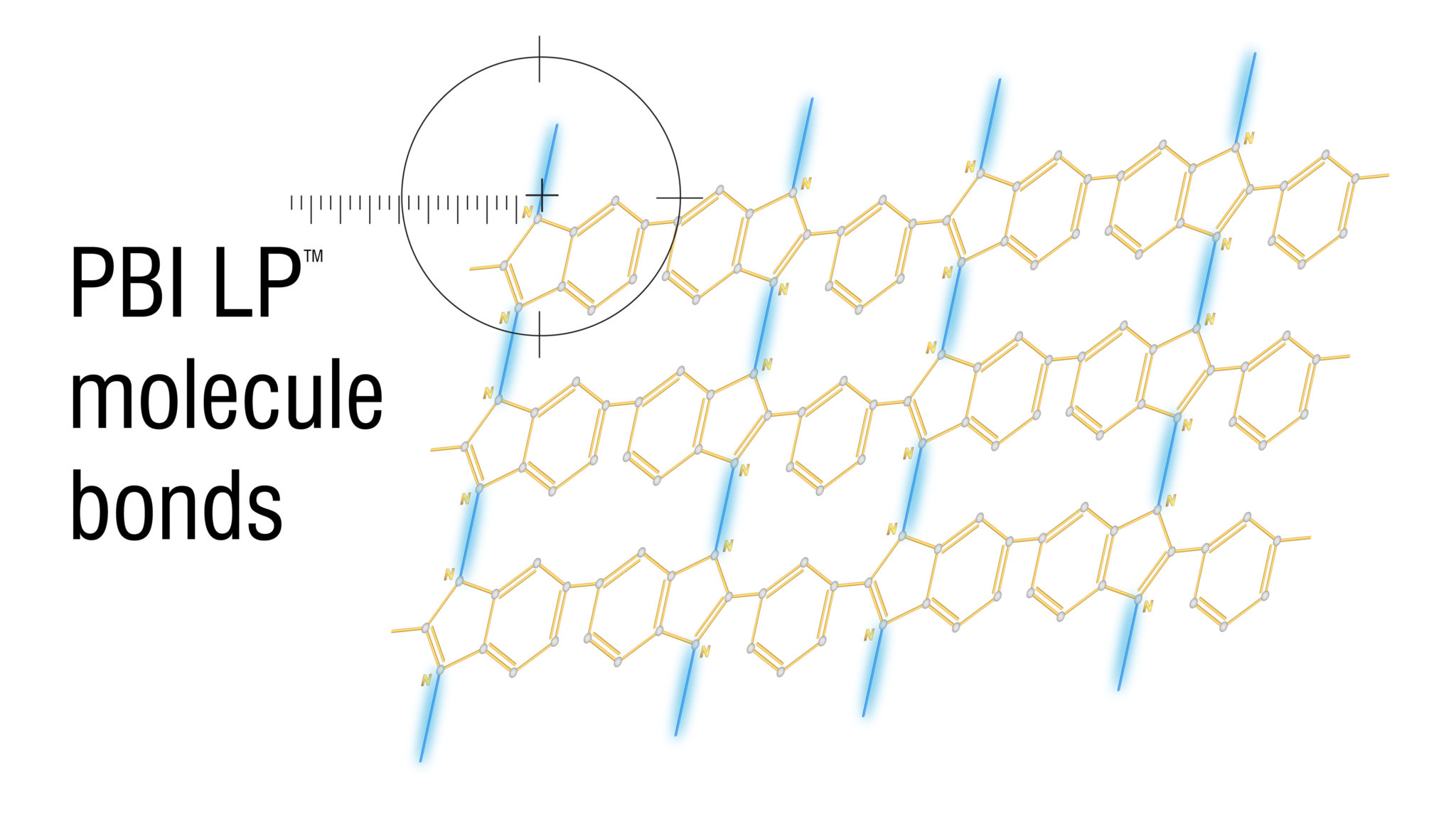

PBI LP Fiber

What is PBI LP? PBI LP is a revolutionary new PBI fiber that raises the bar on break open protection. Compared to traditional PBI fiber, PBI LP exhibits stronger molecular bonds (shown in blue above) for better dimensional stability, increased flame resistance and better break open protection.

The Largest Metro Fire Departments trust in the PBI Max design...departments such as:

Los Angeles

Houston

Phoenix

Philadelphia

San Antonio

San Diego

Austin

Jacksonville

San Francisco

Columbus

Fort Worth

Indianapolis

Charlotte

Seattle

Denver

Nashville

Baltimore

Portland

Oklahoma City

Albuquerque

Tuscon

Tampa

Orlando

Omaha

Mesa

Tucson

Oakland

Kansas City

Montreal

Edmonton

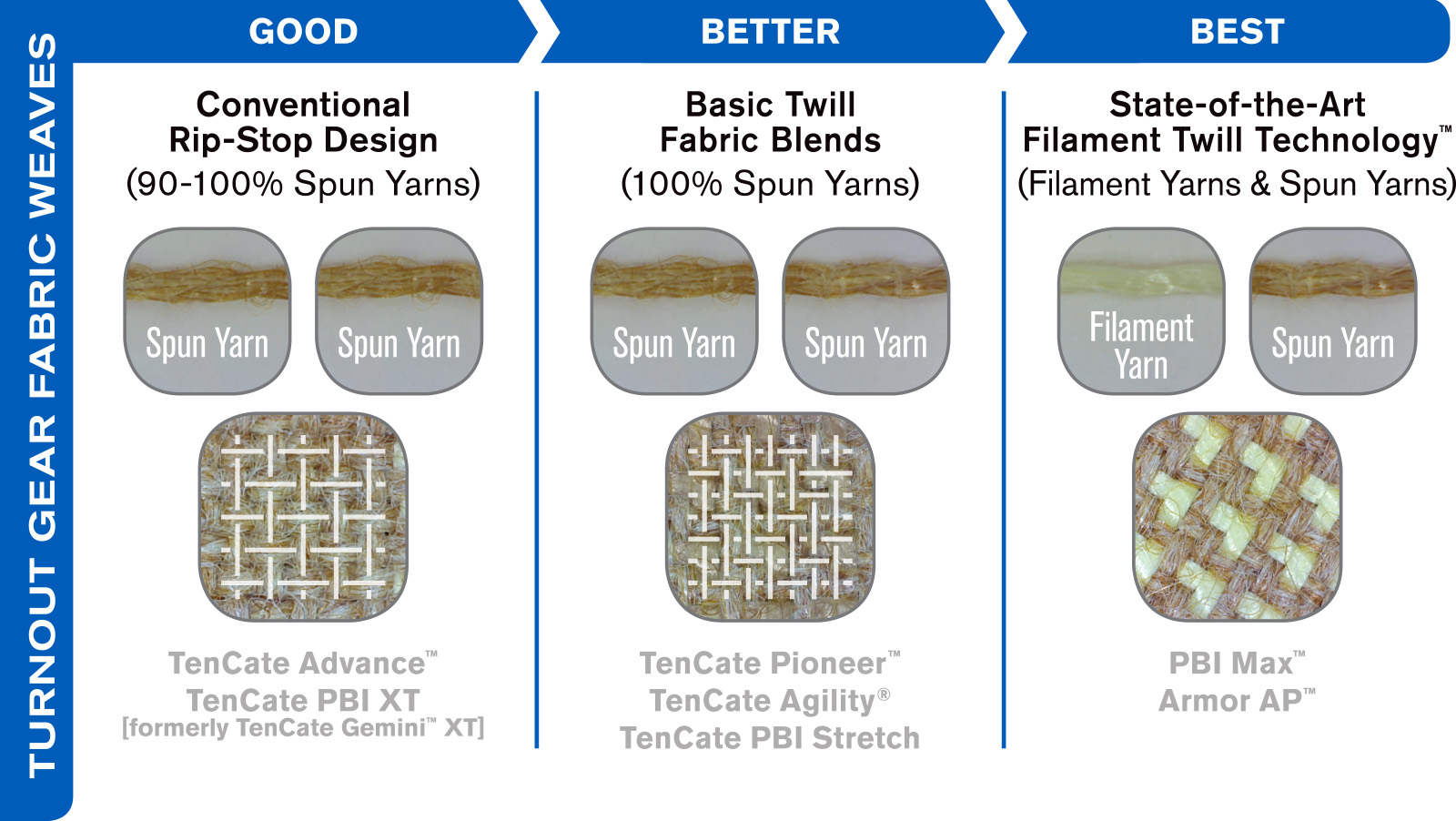

Filament Twill Technology

Filament Twill Technology is a fabric technology patented by Safety Components in 2012. Compared to other fabric technologies like “conventional rip-stop” and “basic twill” designs, Filament Twill fabric designs are lighter and stronger both new and after UV Exposure.