Filament Twill Technology

Uniquely Engineered.

Filament Twill Technology Explained:

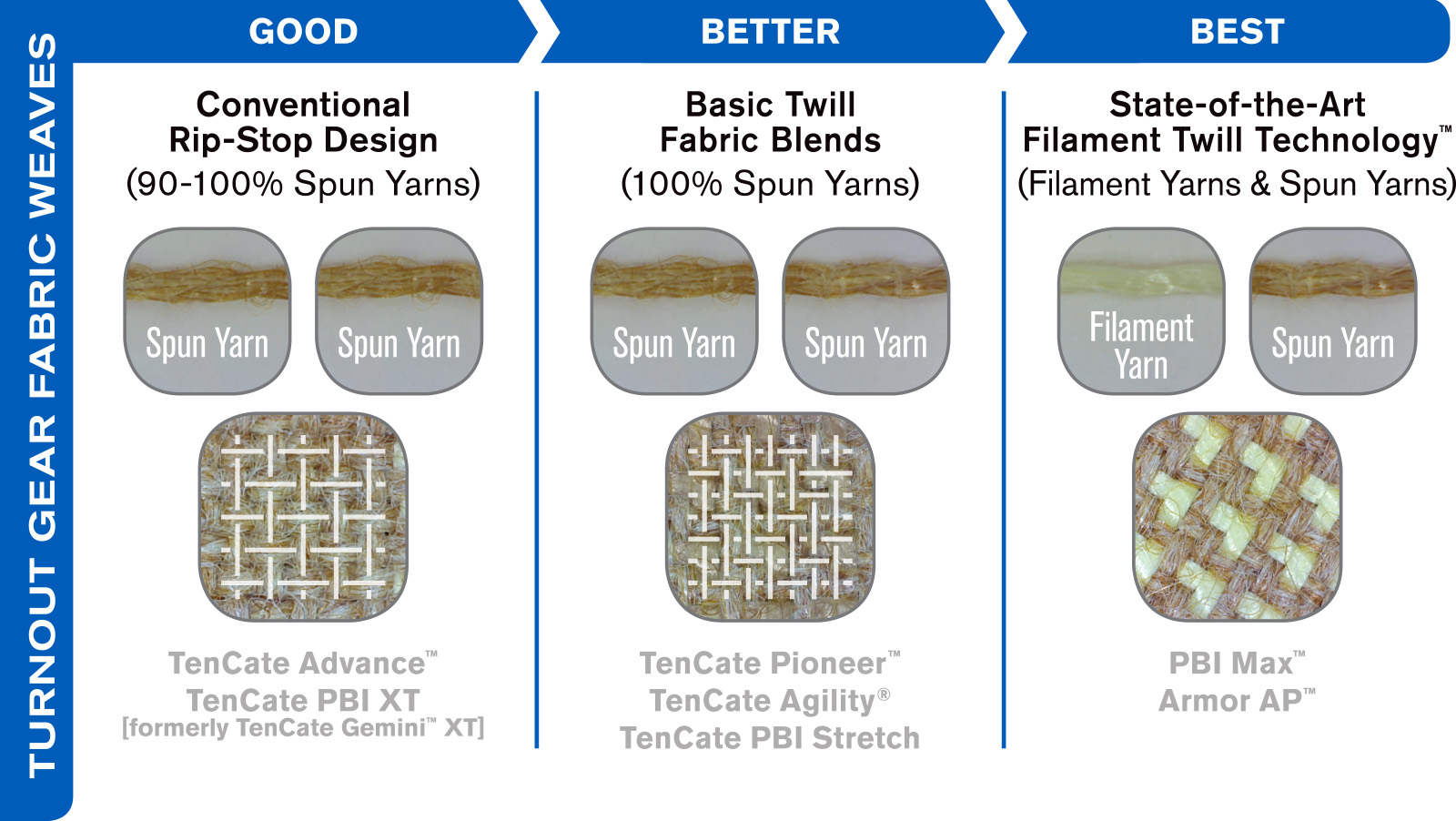

Technology in PPE has advanced at an amazing rate over the last few years. Lighter, stronger, more flexible FR fabrics coupled with ergonomic garment designs have revolutionized the way firefighters perform while wearing turnout gear.

Filament Twill Technology™, developed and patented by Safety Components, can be found in outer shells like PBI Max™ LP and Armor AP™ and in thermal liners like Glide™. Flexible fabrics woven with filament and spun yarns in a twill design are making fabrics made of 90 - 100% spun yarns in a rip-stop weave a thing of the past.

Specify Filament Twill Technology

PBI Max™ LP — 6 oz. [Available in Gold or Black]

Outer shell shall be “PBI Max” designed in a lightweight, 6 oz. twill weave. Outer shell shall be constructed with 70% PBI/Kevlar® spun yarns and 30% 600 denier Kevlar filament yarns. Fabric must be made in the U.S.A.

The results of the “filament twill” weave with 30% 600 denier Kevlar filament leads to tear strength multiple times higher than that of traditional rip-stop constructions. PBI fabrics with trap tear strength under 80 lbs. are not acceptable (as tested by UL).

Dyed fabrics must use Solution or Producer Dyed fiber.

PBI Max™ — 7 oz. [Available in Gold or Black]

Outer shell shall be “PBI Max” designed in a lightweight, 7 oz. twill weave. Outer shell shall be constructed with 70% PBI/Kevlar® spun yarns and 30% 600 denier Kevlar filament yarns. Fabric must be made in the U.S.A.

The results of the “filament twill” weave with 30% 600 denier Kevlar filament leads to tear strength multiple times higher than that of traditional rip-stop constructions. PBI fabrics with trap tear strength under 80 lbs. are not acceptable (as tested by UL).

Dyed fabrics must use Solution or Producer Dyed fiber.

Armor AP™ — 6.5 oz. [Available in Gold, Black, or Khaki]

Outer shell shall be “Armor AP” designed in a lightweight, 6.5 oz. twill weave. Outer shell shall be constructed with 80% Nomex®/Kevlar spun yarns (khaki color contains Nomex/Kevlar/ Teijinconex® spun yarns) reinforced with 20% DuPont™ Kevlar® filament. Fabric must be made in the U.S.A.

The results of the “filament twill” weave with 20% 400 denier Kevlar filament leads to tear strength multiple times higher than that of traditional rip stop constructions. Para-aramid/meta- aramid fabrics with trap tear strength under 65 lbs. are not acceptable (as tested by UL).

Dyed fabrics must use Solution or Producer Dyed fiber.

Glide Ice™

3.6 oz/yd2 Glide Ice™ face cloth consisting of 60% DuPont™ Nomex® filament and 40% DuPont™ Nomex®/Lenzing FR spun yarns quilted as:

7.4 oz. Glide Ice 2-Layer

Glide Ice quilted to 2 layers of DuPont™ Nomex® E89™ spunlace - 2.3 oz./yd2 and 1.5 oz./yd2

7.6 oz. Glide Ice Pure

Glide Ice quilted to 100% quilted meta/para-aramid virgin needlepunched fiber

6.8 oz. Glide Ice with PBI G2™

Glide Ice quilted to 2 layers of PBI/meta-aramid fiber - 1.8 oz./yd2 and 1.4 oz./yd2

6.5 oz. Glide Ice with DuPont™ Nomex® Nano

Glide Ice quilted to 1 layer of 0.6 oz./yd2 Nomex® Nano and 1 layer of 2.3 oz./yd2 DuPont™ Nomex® E89™ spunlace

Filament Twill Technology - Strength

100% Kevlar® filament yarns are over 2x stronger than Kevlar spun yarns. One result of DuPont™ Kevlar® filament in the fabric design is a significant increase in fabric strength both new and after exposure to UV.

Filament Twill Technology - Lightweight Protection

Lighter weight materials with improved protection are possible with Filament Twill Technology. PBI Max LP 6 oz., PBI Max 7 oz., and Armor AP 6.5 oz. offer excellent thermal protection compared to heavier shells proving lighter is better with Filament Twill Technology.